Cleaning

DLP Models

The

DLP models you receive have been cleaned in alcohol and should be ready to trim

and primer. If you notice any small residue spots on the surface, you can do a

quick IPA (isopropyl alcohol) rinse. Do not soak the models in alcohol, the

plastic will absorb it causing warpage. If that happens by accident, let the

model fully dry and it should return to normal.

Trimming

Models

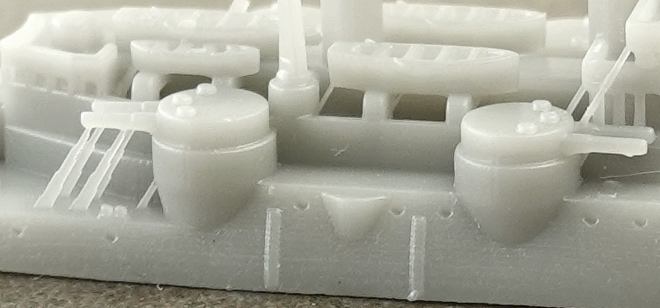

DLP models will need to have their many tiny support sprues

manually removed before priming and painting. The best way to remove them is

with a very fresh, sharp razor blade and a fresh #11 x-acto knife. First use

the razor blade corner to slice the top (or bottom) of each support - for gun

barrels I usually use the very corner of the fresh razor blade to first gently

slice through the support where is joins the barrel. Once you have cut most or

all of the way through one end of the support, you can use the x-acto knife to

leverage away the rest of the support. Careful use of the razor corner is the

best way to remove the supports without snapping off fragile features (if

any).

|